Stainless Steel 304H Socket Weld Flanges

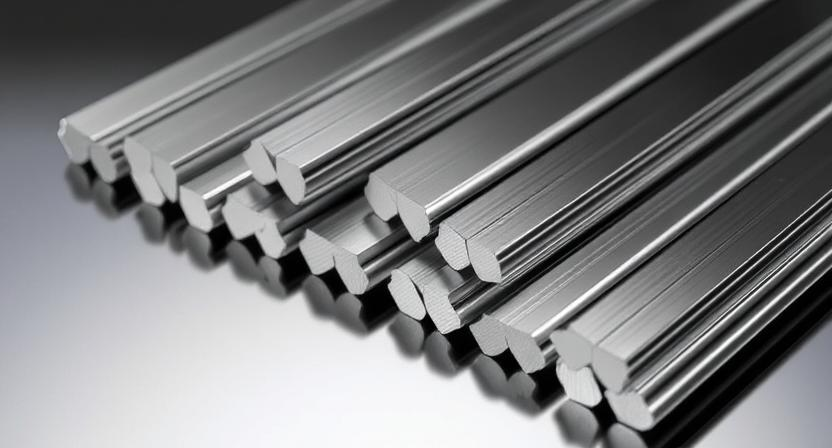

Ferrobend has developed a robust manufacturing process for producing 304H stainless steel socket weld flanges that ensures high precision, reliability, and durability. Here’s a detailed look at the process that goes into crafting these premium products. The first step in manufacturing stainless steel 304H socket weld flanges is selecting the highest-quality raw material. Ferrobend sources stainless steel 304H from reputable suppliers, ensuring that the material meets international quality standards. This step is crucial for achieving the desired mechanical properties and corrosion resistance in the finished flanges.

Ferrobend uses advanced CNC equipment to perform complex operations like drilling the central hole for the pipe, cutting the bolt holes, and creating the socket or recess for the pipe to fit into. This step is critical in achieving the high-quality standards that Ferrobend is known for.

Heat treatment is another important stage in the production of stainless steel 304H socket weld flanges. This process helps enhance the material’s hardness, tensile strength, and resistance to thermal expansion, ensuring that the flanges perform well under high-pressure and high-temperature conditions. Ferrobend uses precise heat treatment procedures to ensure consistent material properties across all of their flanges.

Quality control is a critical part of Ferrobend’s manufacturing process. Each 304H socket weld flange

undergoes a series of stringent tests and inspections to ensure that it meets both industry standards and

customer specifications. This includes visual inspections, dimensional checks, and mechanical testing,

including tensile strength, hardness, and pressure testing.

Ferrobend also employs non-destructive testing (NDT) methods such as ultrasonic and radiographic testing to

identify any internal flaws or imperfections that could compromise the performance of the flanges. This

ensures that only the highest-quality products are delivered to customers.