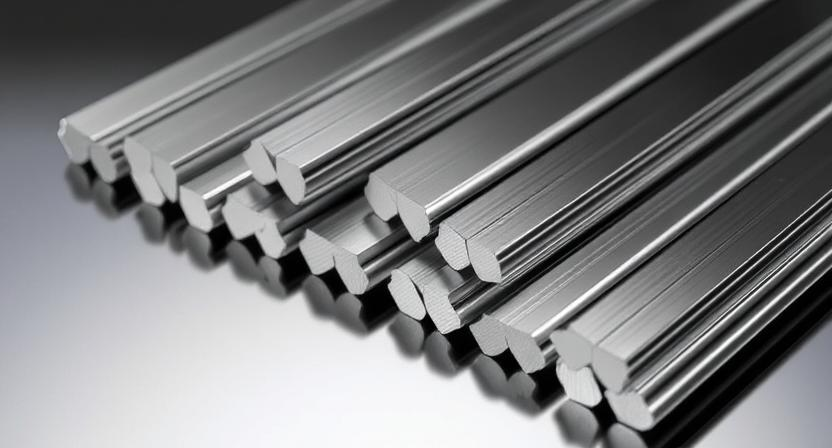

Stainless Steel 304H Threaded Flanges

At Ferrobend, the manufacturing process begins with the careful selection of high-quality raw materials. Stainless Steel 304H is sourced from top-tier suppliers, ensuring that the material used for threaded flanges meets the highest standards of strength, durability, and resistance to corrosion. Ferrobend conducts stringent testing and quality checks to ensure that the raw materials are free from defects and impurities. Ferrobend is renowned for its expertise in producing stainless steel flanges, particularly Stainless Steel 304H threaded flanges, which meet international standards and customer specifications. The company’s dedication to quality and precision has made it a trusted partner for industries around the world.

Threading is a crucial step in the production of threaded flanges. Ferrobend uses state-of-the-art CNC turning machines to cut internal threads on the flange. These machines are capable of achieving fine, precise threads that match industry standards for threading tolerances. The threads are critical for ensuring a secure and leak-proof connection with the mating pipe or valve. Ferrobend’s ability to achieve consistent and accurate threads is one of the reasons why their flanges are in high demand.

Ferrobend places a strong emphasis on quality control throughout the manufacturing process. Every stainless

steel 304H threaded flange undergoes rigorous testing to ensure that it meets the specified standards for

dimensions, mechanical properties, and surface finish. This includes visual inspections, dimensional checks,

and material composition analysis. The flanges are also tested for pressure, ensuring they can withstand the

stress and pressure associated with the intended application.

Ferrobend also conducts non-destructive testing (NDT) to check for potential defects such as cracks or

internal voids, which could compromise the flange’s performance. The company’s adherence to strict quality

control protocols guarantees that every product leaving their facility is of the highest standard.

Ferrobend offers custom manufacturing solutions to meet the specific needs of their clients. Whether it's custom sizes, unusual threading requirements, or specific finishing processes, Ferrobend’s team of experts works closely with customers to deliver tailored solutions that fit perfectly into their piping systems.